Change Language :

Reliable energy supply and maintenance-free plain bearings for stage technology

Areas of use

Top products for stage technology

Microphone winch e-spool microphone

- Uninterrupted sound transmission without slip ring

- Cable easy to replace

- Simple and space-saving installation, no additional support equipment required

- No manual work at height

- Available with one cable or as a stereo version with two cables for connecting two microphones

Cable drum for e-chains without slip ring

With the e-spool, moving stage technology can be supplied with different media without interruption. The system is used for stage platforms, movable lighting hoists or video cubes. The inserted cables are guided through a twisterband so that no slip ring is required. This offers a particular advantage when transmitting data. The length of the reeled energy chain is adjusted by a return spring for a stroke of up to 15 metres and by a motor for a stroke of up to 25 metres and more. Placed on the rigging loft, in suspended ceilings above the auditorium or in the understage area, the system operates unobtrusively out of sight of the audience.

- All media in one system: Power... Data... FIBRE OPTIC...

- Deflectable energy chain for a wide range of applications.

- Quiet and low-vibration.

- Simply add or replace cables.

- Fully harnessed with cables and connectors on request.

- Manufactured in accordance with the DIN EN 17206 standard and DGUV principle 315-390.

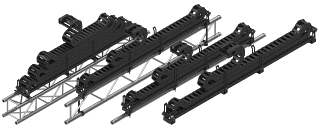

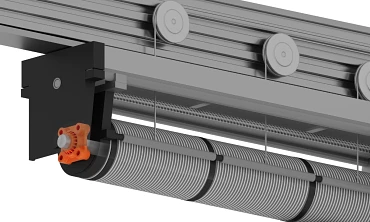

Zig-zag systems

As an alternative to e-spool, we offer various zig-zag systems – including our classic system, which has proven its worth on stage for many years and has been in use at the Royal Opera House in London since 1998. With this space-saving system, different media can be guided simultaneously without interruption and with no slip ring. The energy chain unfolds during the stage machinery's vertical movement. We have also been offering a low-cost version since 2024. The system has all the advantages of an e-chain with an innovative guide concept for travels of up to 10m. In the upper machinery, the guide box is mounted on the tie rod or shaft end support, in the lower machinery on the floor below the podium.

- Quiet and low vibration

- No tensile strain on the cables

- Simply add or replace cables

- All media in one system: Power ... data ... fibre optics ...

- Customised systems with up to 40m travel available

Find out more about our zig-zag systems

Standard complete system

With up to 15 metres of travel

Low-cost versions without guide box

Around 50% weight and cost savings compared to the standard version

white paper

Vertical energy supply in stage technology

Like every industry, stage technology has its very own requirements for machine parts and materials. In this white paper, we give you 6 tips for the selection and design of vertical energy supply for stage technology

Cables for theatre and stage technology

Safe performances guaranteed thanks to special cables for the requirements of stage technology! The cables are designed to withstand small bend radii and high loads. There is also a separate series of cables (CFSPECIAL.381) specially developed for theatres, which has three bus cables in its range with a black outer jacket.

- Cables for small installation spaces, developed and tested for use in our energy chains

- Reliability through durability: we test our products in our in-house test laboratory so that you can rely on your technology

- Inconspicuous black bus cables CFSPECIAL.381 as CAT6, CAT7 and 2-channel cable for DMV control applications

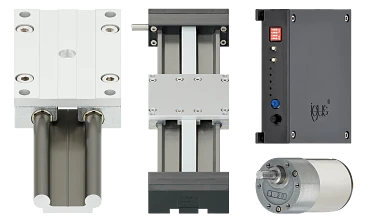

Linear technology for camera sliders

A motorised camera slider is a popular tool for smooth camera movements that run precisely and automatically. You can either use a ready-made system or assemble your own slider individually. We offer the right components for this – with lubrication-free sliding elements that are up to four times quieter than recirculating ball bearing systems.

- Simple, manually operated sliders can be customised from our drylin W modular linear system

- If automation, remote control and greater precision are required, we offer linear axes with toothed belt drive and the matching motor with control system – as a cost-effective Advance or high-quality Professional version

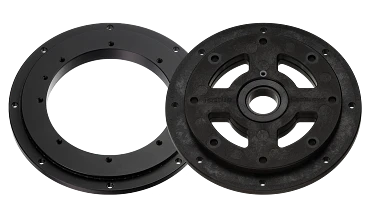

PRT slewing ring bearings for 360° movements

Our slewing rings are equipped with maintenance-free, tribologically optimised sliding elements made of plastic instead of the usual metal rollers or balls. They have the advantage of being quieter and saving weight. This makes them ideal e.g. for pan movement in moving lights. Our cost-effective 05 series made of solid plastic weighs just 76g, making it a real lightweight.

- Elegant and discreet: Black Edition made of aluminium, coated black, with black universal slide elements made of iglidur JB:

PRT-04 slewing ring in black - Extra-light low-cost version: Solid plastic, made from at least 97% regranulate:

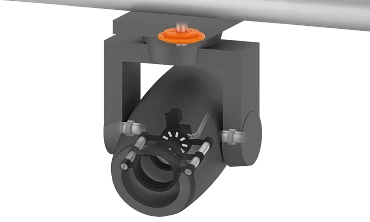

Self-aligning flange mounted bearings

igubal flange mounted bearings are a lubrication-free, efficient solution for shaft bearings in the theatre and stage technology. They are used in drum winches, for example to precisely align diffusers for optimum room acoustics, or in vertical curtain lifts for stage curtains. The bearings compensate for misalignment and are a cost-effective, maintenance-free and quick-to-install alternative.

- Top seller: igubal KFSM four hole flange bearing with split housing:

- Quick and easy to install

- Spherical ball is made of iglidur J with low friction values in dry operation and an extremely low stick-slip tendency

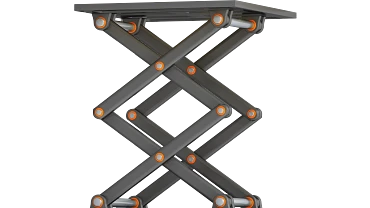

Two-component heavy-duty plain bearings

Our iglidur Q3E multi-component bearings are the right choice for use under very high loads, for example in scissor joints of stage platforms.

- High mechanical strength with low wear

- Cost-effective due to injection moulding production

- Lubrication-free dry running without maintenance

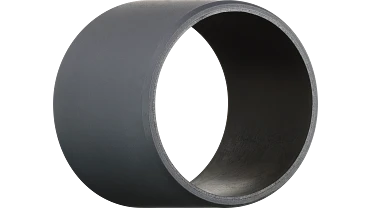

Clearance-reduced plain bearing

Bearings made from our new iglidur G2 material achieve a particularly high level of precision. Thanks to a particularly low moisture absorption and temperature expansion combined with high dimensional stability, they enable a very low bearing clearance (G9) - ideal for rattle-free haptic applications.

- Up to 40% more cost-effective than comparable metal bushings

- Approx. 40% clearance reduction compared to iglidur G

- 100% lubrication-free and maintenance-free

Exhibition stand for stage technology

Experience products virtually - alone or with a guide

Did you miss the last trade show for stage technology? We have the solution. Simply visit our exhibition stand for stage technology in Cologne online.

Successfully in use with our customers

Tested for use in the test laboratory

All products are tested for wear and load capacity under real conditions in the igus test laboratory, the largest in the industry. The results flow into our tools for calculating service life and enable precise predictions to be made about durability.

Upon request, igus also carries out customer tests to test the use of the products under very individual conditions.

Consulting

I look forward to answering your questions

Treotham Automation Pty Ltd. (Distributor)(64) 7849 0281Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr