Change Language :

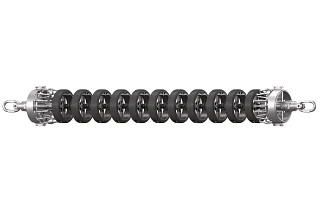

Reliable e-loop® cable guidance for top drives

Weather resistance with easy maintenance, assembly, and disassembly

Getting oil out of the ground requires deep drilling rigs with top drive systems. They often involve extreme conditions: wind and weather, dirt, and harsh handling of systems and equipment affect machine components. For cable guidance, manufacturers and operators have so far relied on service loops, which often entail a number of problems. Cables can move in the service loops, which have no defined bend radius. In extremely windy conditions, the freely hanging service loop can get caught in the mast or lighting system and be torn off. Another problem is that the entire hose package must be replaced if one hose is defective. To reliably guide cables, even those with large cross sections and great weight, in hanging applications, igus has developed the e-loop.

The e-loop combines the advantages of a plastic energy chain with those of a high-strength pull rope. The pull forces are transmitted to the mounting brackets and the structure by the pull rope inside the energy chain. The e-loop is used not only in the oil and gas industry, but also in the offshore industry, shore power supply, construction machinery and wind turbines.

- Safely guide cables in one system

- Weather-resistant and dirt-resistant

- Protection against impact thanks to robust PU outer body

- Cables can be added or replaced, even during operation

- Double screw locking on all elements for high operational reliability

How the e-loop is constructed

1) The inner body consists of four injection-moulded parts. Two of these form the crossbar in the chain link and are screwed together (to prevent loss). The screw connection clamps them onto the pull cable.

2) Outer protectors made of impact-absorbing PU ensure that the energy chain and cables are protected in the event of hard impacts.

- The individual chain links are clamped onto the high-strength pull cable. The cable itself is a plastic fibre cable and has a permissible tensile load of 50kN.

- The mounting brackets of the e-loop are strong steel mounting brackets. The plastic fibre cable is integrated into them, which absorbs the entire tensile strength of the e-loop.

To e-loop product selection

Dynamic, with crossbars every link | For almost all applications

1Applies to chain lengths of up to 50 metres. Max. additional load for longer energy chains upon request.

| Part No. | Inner width Bi [mm] | Outer width Ba [mm] | Bend radius [mm] | Cable diameter [mm] | Fill weight [kg/m]1 |

|---|---|---|---|---|---|

| ELP.220.01.D | 150 | 220 | 380 | 38 | 50 |

| ELP.300.01.D | 230 | 300 | 500 | 75 | 50 |

| ELP.430.01.D | 360 | 430 | 680 | 108 | 70 |

| ELP.TD.300 | 230 | 300 | 500 | 75 | 50 |

Static, with crossbars every 2nd link | For purely static cable guide

1Applies to chain lengths of up to 50 metres. Max. additional load for longer energy chains upon request.

| Part No. | Inner width Bi [mm] | Outer width Ba [mm] | Bend radius [mm] | Cable diameter [mm] | Fill weight [kg/m]1 |

|---|---|---|---|---|---|

| ELP.220.01.S | 150 | 220 | 175 | 38 | 50 |

| ELP.300.01.S | 230 | 300 | 210 | 75 | 50 |

The most fascinating projects with e-loop

In-house test laboratory for the e-loop

FAQ – Frequently asked questions about e-loop

A service loop is used to guide cables and hoses in hanging applications, e.g. as an energy supply on the top drive. For this purpose, the cables are often moulded together in a hose package.

To ensure that cables with large cross sections and heavy weights can be safely guided in hanging applications, igus has developed the e-loop as an alternative to the service loop. The energy supply system is a round, three-dimensional modular system that can move cables with a defined bend radius without strain. The cables can be used individually and replaced during maintenance. The chain links can also be replaced at any time.

The new energy supply from igus is built around a high-tensile plastic rope that absorbs the tensile forces of the cables. The rope consists of a synthetic plastic fibre, making it break-proof, weather-resistant, flexible and corrosion-free.

Unhook, lay down, unscrew, exchange cable(s), screw shut, remount. Maintenance is complete thanks to the simple modular design of the energy chain. In case of an emergency, a replacement chain should always be available to prevent downtime.

igus delivers the e-loop the way you want it: either completely assembled or harnessed, on a drum or pallet. There is a defined thread at the end of the e-loop for additional mounting. Our installation team is happy to take care of the assembly.

The individual chain links are all secured with screw connections so that no components can fall off.

Consulting

I look forward to answering your questions

Treotham Automation Pty Ltd. (Distributor)(64) 7849 0281Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr