Change Language :

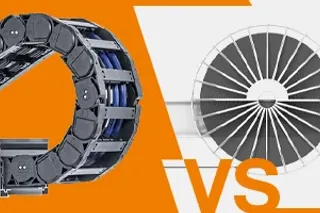

Energy chain systems instead of motorised cable reels

Save costs on long travel distances with energy chain systems

Motorised cable reels or cable reels can be used as an energy supply for long travel distances - for example in the bulk goods or crane industry. They are relatively easy to install and generally do not require a guide trough to keep the cable on the desired path. igus®, a manufacturer of components made from high-performance polymers, offers complete energy chain systems as an alternative to motorised cable reels, which are particularly advantageous for long travel distances.

White paper: energy chains vs. motorised cable reels

The advantages and disadvantages of both energy supply systems in industry

Whenever designers have to guide hoses and energy and data cables in moving applications with long travel distances of over 100 metres, the question arises: Which cable carrier system is the most efficient - in terms of reliability, ease of maintenance and future-proofing, among other things? A motorised cable reel? Or an energy chain? The advantages and disadvantages of both systems.

What is the difference between motorised cable reels and energy chain systems?

Why are energy chain systems best suited for long travel distances?

No slip ring required

Energy chain systems have no slip ring, which is the reason it is also possible to transmit media such as air, water and oil without interruption.

All in one system

Various cables and hoses for energy, data and media can be safely managed in one system and individually replaced or supplemented if necessary.

Dynamics

A motorised cable reel can run at a speed of approx. 300 m/min. For the first few metres, the pace must be reduced for safe rolling. For medium feed, this means that the system must be braked and accelerated halfway. With an energy chain system, travel speeds of up to 600m/min are an option, and this is possible fully without any restrictions on the loads or speeds at start-up.

Motor / Control system

Energy chain systems do not require their own drive, they are simply attached to the moving part of the system and carried along.

Space-saving

Depending on the travel/cable length, a motorised cable reel has a diameter of up to 8 metres. In addition, space is required for the motor and the slip ring body. In the case of an energy chain system, irrespective of the travel, only one moving arm is required on the crane - which is integrated in the installation space of the crane - and the installation space for the trough of the chain on the ground.

Cable length

In medium feed, half the travel length plus 20 metres reserve must be calculated as the cable length for motorised cable drums. In energy chain systems, one also calculates with half the travel length, but with only two metres in addition, which are needed for the radius of the chain. At higher travelling speeds (over 60 m/min.), however, end-fixed is recommended for motorised cable reels. This increases the cable length to the total travel length plus 20 metres reserve.

For maximum service life with optimised design - P4HD.56R heavy-duty roller chain

The new heavy-duty roller chain fulfils all the requirements that apply to container cranes of the next generation and beyond.

Ever longer distances, higher dynamics, short load cycles, zero failures: That, in a nutshell, is what manufacturers of ship-to-shore container cranes demand for energy chain on crane bridges. The new P4HD.56R fulfils these requirements - with maximum cost-effectiveness.

How do I find the right energy chain system?

The range of energy chain systems is huge. In order to find the right solution for your application,

we ask you to fill in the form with some basic information. You will then receive personalised advice from

personalised advice from one of our experts.

From individual parts to complete systems

More information

Consulting

I look forward to answering your questions

Treotham Automation Pty Ltd. (Distributor)(64) 7849 0281Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr