Change Language :

Frequent cable defects in moving applications

Broken wires

Core rupture is the failure of electrical conductivity in cables due to broken copper wires caused by mechanical overloading/tensile strain of the individual cores under continuous bending stress.

Core rupture is usually caused by incorrect stranded wires and/or incorrect pitch directions and lengths. Although the use of stranded wires that are too thin offers more flexibility, it can lead to breakage in the long term. igus® relies on an optimised combination of individual wire diameter and pitch direction or pitch length, which has resulted from endurance tests in the igus® test laboratory.

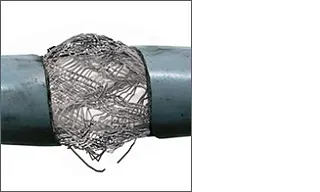

Corkscrew

A corkscrew is the term used for an externally recognisable screw-like deformation of the entire cable caused by mechanical overload/tensile strain during the bending process. A corkscrew is usually caused by a faulty cable structure. Cores wound in layers, an outer jacket extruded onto a hose or a missing core can lead to problems here. In addition, an application outside the specified parameters (bend radius too small, travel too long) can lead to corkscrews.

To avoid corkscrews, igus® relies on cores wound in bundles for cables with more than 12 cores. The cores are stranded several times and therefore change the inner and outer radius of the bent cable several times at the same distance. This ensures that the tensile and compression forces are compensated and significantly extends the service life of a cable.

Insulation damage

Insulation damage can cause short circuits in electrical cables due to damage to the insulation around the conductor. This can be caused by material fatigue under continuous bending stress or material abrasion within the stranded structure. Single wire breaks in the conductor or the braided shielding lead to puncturing of the insulation.

To prevent insulation damage to the core insulation, materials such as TPE or PVC are used that do not stick together. The insulation materials are also tested in millions of test strokes in the igus® test laboratory.

Jacket damage

Jacket swelling or jacket damage refers to damage to the outer jacket of a cable. The jacket becomes soft and misshapen or breaks until the stranding or the shield can be seen. This can be caused by the wrong choice of material in terms of the oils or other chemical materials used. An ambient temperature that is too low can also lead to jacket damage if the temperature is too far below the minimum temperature specified in the data sheet. As soon as jacket swelling or jacket damage occurs, the cable must be replaced immediately.

To avoid jacket breakage, it is recommended that the temperature range and oil resistance of a cable be considered first and foremost. If cables are used in oil-free environments, non-oil-resistant PVC cables are sufficient, provided the permanent ambient temperature is above 5°C. If cables come into contact with oils, chainflex® cables with a PUR or TPE outer jacket are recommended. Cables with a TPE jacket are also resistant to organic oils. The oil resistance of all chainflex® cables is specified according to DIN standards. These jacket materials are also suitable for temperatures of -25°C (PUR) or even -35°C (TPE) for permanent use in the energy chain.

Shield wire breakage

Shield wire breakage is the term used to describe overloading of the shield wires that protect a cable from the effects of electromagnetic compatibility. The consequences of a break range from reduced shield effectiveness to short circuits when sharp wire ends pierce through the non-woven fabric or foils into the core. The cause is often an unfavourable braid angle. If the shield can be easily pushed over the jacket after the stripping process, this is a sign that the cable is not suitable for use in energy supply systems.

In order to prevent shield wire breakage, igus® has conducted long-term tests to determine a braid angle that is as flat as possible as the optimum shield braid angle for energy chain-compatible cables. This angle neutralises the tensile forces and is therefore suitable for energy chains. The strong inner jacket provides additional protection so that the shield cannot move uncontrollably.

Consulting

I look forward to answering your questions

Treotham Automation Pty Ltd. (Distributor)(64) 7849 0281Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr