Change Language :

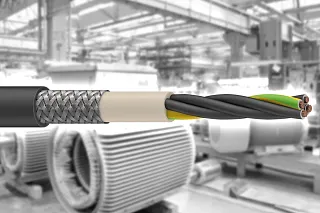

Motor cables for the energy chain

A motor is supplied with energy via a motor cable that contains cores – three black cores for Phases L1, L2, and L3 and a green/yellow core for the earth core. Today, coil windings in the motor are usually interconnected to form a star or triangle. This is how the number of cores is limited to four.A cable with or without shielding can be selected, depending on cable requirements with respect to interference or environment sensitivity. And, of course, the cable is manufactured with a variety of jacket qualities and mechanical classes.

Why motor cables?

When professionals talk about motor power, they usually don't just mean a supply cable for a motor. A four-core control cable can also represent this. The point is that you want to connect the motor to a frequency converter (FI). The prerequisite for this is that the insulation of the core fulfils the voltage level of 600/1000V. This is necessary because the frequency converter uses the principle of pulse width modulation to regulate the frequency and therefore the motor speed. This leads to voltage peaks, which the insulation must be able to withstand. For this reason, a higher voltage class is selected than that of a control cable.

Multi-core vs. single core

For large drives in particular, it is now common to run the cable in single cores. This solution offers several advantages over the classic four-wire multi-core. The biggest advantage is probably the significantly lower price, which is achieved through a different, cost-effective manufacturing process. The single-core solution is also robust and therefore suitable for small installation spaces in the energy chain, while at the same time offering a longer service life. This is particularly noticeable on long travels. The connection to the motor is easier with the thinner single-core cables, but requires a special screw connection. We are very experienced with challenges of this kind and therefore always have the required products for the solution in stock.

Advantage of TPE for abrasion, cold and service life

The majority of our motor cables have the high-end material TPE as the outer jacket material. This material is particularly suitable for applications in extreme temperature ranges. This is because the temperature range for TPE motor cables is defined in energy chain as -35°C to +90°C. This means that applications in deep-freeze areas or applications in very warm environments are just right for this material. In addition, TPE has another special feature - maximum abrasion resistance. In direct comparison to PVC & PUR, TPE has better abrasion behaviour and is therefore ideal for high-end applications for the highest service life.

Motor cables in crane systems

igus has been equipping crane systems with energy chains for many years. Well over 10,000 crane systems worldwide have been in continuous use for many years. The cable and chain withstand the most adverse conditions, from -40°C in the Siberian winter to 50°C in Dubai harbour. A cable failure is unimaginable in crane and trolley operations. Maximum reliability is required in these areas. For this reason, single cores from the CF330.D or CF340 series are used throughout to supply the hoist with nominal conductor cross sections of up to 185mm. This can be seen as a development towards standardisation. The next time we plan an application with a large cross section, we should definitely discuss a concept with single cores that have a high-quality braided conductor.

Haven't found the right one yet?

Do you already know our online tool?

Easy to find, select the right type, calculate service life and order online

Product finder

Find exactly the right cable quickly

Service life calculator

Calculate the service life of any chainflex cable

Copper surcharge calculator

Calculate the daily copper surcharge

Configurator for customised cables

Configure your customised cable in just 3 minutes

Are you still looking for an energy chain for your cable?

Click here to go to the energy chain shop

... or everything ready harnessed as a readychain?

To the readychainConsulting

I look forward to answering your questions

Treotham Automation Pty Ltd. (Distributor)(64) 7849 0281Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr