Change Language :

Threaded rods from dryspin® in 3 variants

What exactly is a threaded rod?

A threaded rod is a cylindrical round rod with a male thread. It is used to fasten objects or as a simple drive system in the form of a moving thread. In Europe, threaded rods usually have a metric ISO standard thread, for example according to DIN 13-1. However, there are many other threaded rods according to other standards, such as the UNC thread according to the American ANSI/ASME standard. Last but not least, a trapezoidal threaded spindle according to DIN 103 is also a threaded rod.

The type of thread is defined by the profile shape, the pitch, the number of turns and the direction of rotation. Further terms relating to the thread can be found in our blog post. The threaded rod can be shortened or machined very easily, which makes it a popular and versatile product. Their applications range from model and furniture construction to mechanical engineering and the fastening of heavy loads such as shelving systems, railings, steel structures or stairs. In building construction, the majority of building services are suspended using threaded rods. Threaded rods are usually firmly anchored, e.g. For example, in concrete in order to subsequently fasten an object.

In addition to the threaded rods used for fastening purposes, there are also threaded spindles such as trapezoidal or high helix lead screws, which are used as moving threads. In common parlance, these threaded spindles are often referred to as threaded rods. In fact, lead screws convert a rotational movement into a translational movement (motion thread). Compared to threaded rods such as the metric threaded rod, threaded spindles are significantly more efficient and suitable for a permanent dynamic load. Lead screws are usually driven by handwheels or motors.

Do you need an individually configured threaded rod? We have the solution.

Threaded rod with steep thread

The steep threaded rods are part of our dryspin® range, which is specially designed for fast and very efficient applications. Thread sizes from DS4x2.4 to DS18x100 are available. The standard material of the dryspin® threaded rods is stainless steel AISI 304, AISI 304, which makes them 100% corrosion-free and minimises wear. The threaded spindles are also available in aluminium. The threaded rods offered by igus® are generally rolled. The advantages of this manufacturing process, such as good surface quality and cost-effective production, are ideally suited to the lubrication-free lead screw nut made from tribologically optimised plastic. The steep threaded rods are available in right-hand, left-hand and reverse threads.

- Longer service life due to thread asymmetry

- Higher efficiency compared to conventional trapezoidal threads

- Not self-locking

Explanation of dryspin® technology

High efficiency and low wear

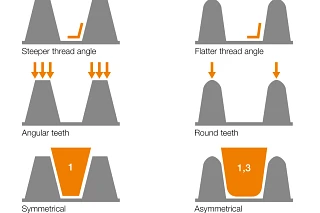

The patented dryspin® steep thread technology was developed by igus® in 2013 and offers numerous advantages over conventional steep threads. Due to the flat flank angle, it efficiently converts the applied force into a translational movement. With the specifications and geometries matched to the plastic nut and spindle, dryspin® offers even greater service life and efficiency for steep threads. Thanks to the rounded tooth flank geometry, the contact surface between the threaded spindle and lead screw nut is reduced and the threaded systems run almost silently and vibration-free under load.

The larger distances between the individual dryspin® threads increase the proportion (factor 1.3) of tribologically optimised polymer in the threads. More wear-resistant material and a higher degree of efficiency are decisive for a service life that is up to 5 times longer than that of conventional steep threads.

Threaded rod with trapezoidal thread

In the cross section, the trapezoidal thread corresponds to an isosceles trapezoid with an angle of 15°. The flank angle is 30°. Compared to the standard thread, the trapezoidal thread spindle has a larger diameter and a larger pitch. The lead angle of single start trapezoidal threaded spindles is smaller than the arc tangent. This ensures self-locking. Double start lead screws, on the other hand, are not self-locking.

Our trapezoidal threaded rods are available in aluminium EN AW 6082, CF-15 steel (AISI 1015) and stainless steel. The dryspin® trapezoidal threaded spindles are manufactured rolled as standard and we offer them in right-hand, left-hand and reverse thread directions.

Threaded rod with metric thread

In Europe, the metric ISO thread has become established, also known as the standard thread, normal thread or pointed thread. The outer edges of this thread form converge in a wedge shape. The metric ISO thread is self-locking due to this profile shape. The flank angle between two threads is 60°. Like the thread pitch, the diameter is specified in millimetres and marked with an M (e.g. M8). The thread, which is defined in DIN 13, is used for friction-locked connections. The metric threaded rods are available from us in right-hand thread and stainless steel 1.3041.

- Available in thread sizes M3 to M6

- Available from standard thread to fine thread

- Fine threads are not standard with us, but are of course possible on request

Consulting

I look forward to answering your questions

Treotham Automation Pty Ltd. (Distributor)(64) 7849 0281Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr